The 3D-Printed 35mm Film Camera brings back the good old days of movies.

(Image credit: Blaž Semprimožnik)

Have you ever desired to create a film similar to those produced by Hollywood using Arriflex cameras? Only to be shocked by how much film costs? Bla Semprimožnik is an electronics tech who might be able to help you.

Semprimožnik has made a 3D-Printed 35mm Film Camera that can shoot up to a minute of footage at 18 frames per second. Even better, this camera can shoot color or black-and-white rolls, short films, time-lapse, or even single 35mm frames. And what’s the cherry on top? It’s ready to use as a scanner right away. A complete camera system, in only one device!

The camera was made to be a cheap way to shoot and scan 35mm films. In his YouTube video (below), Semprimožnik says, “A couple of years ago, I rarely shot 35mm films with point-and-shoot still cameras, but I also wanted to shoot motion picture films.

“I considered what I could do and figured that Super8 film would be the best way to do it. But when I thought about how much it would cost, I realized I wouldn’t be able to get by with just one normal 50-foot clip. The cost of buying, making, and digitizing just one would be more than €100 [about $110, £100, or AU$190]!”

Design & Internal Building of The 3D-Printed 35mm Film Camera

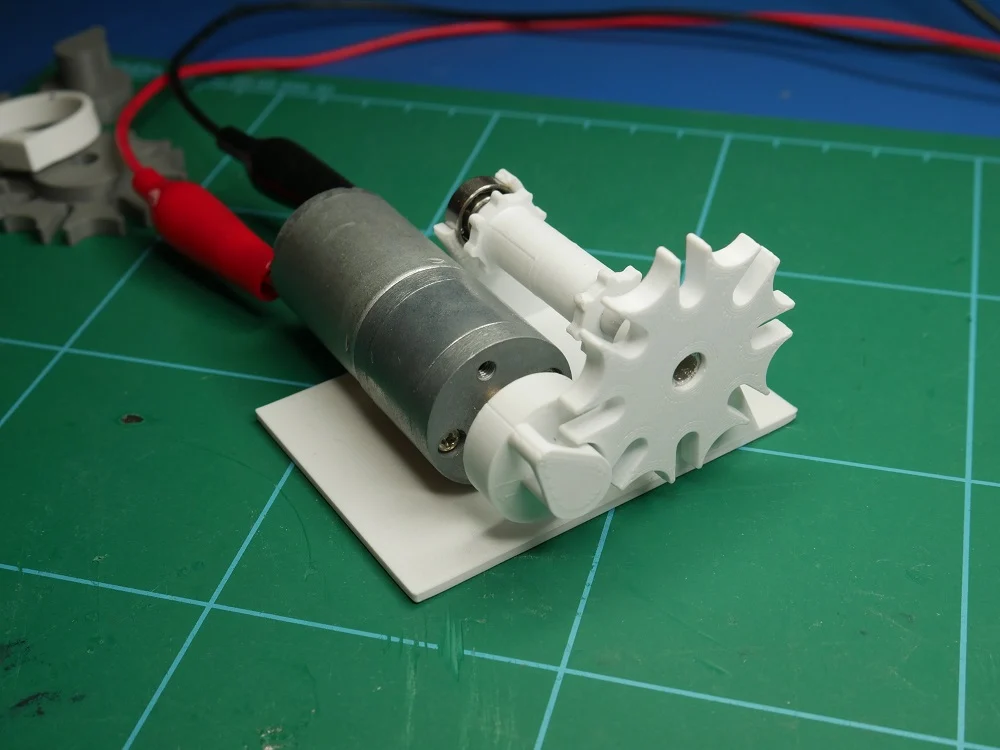

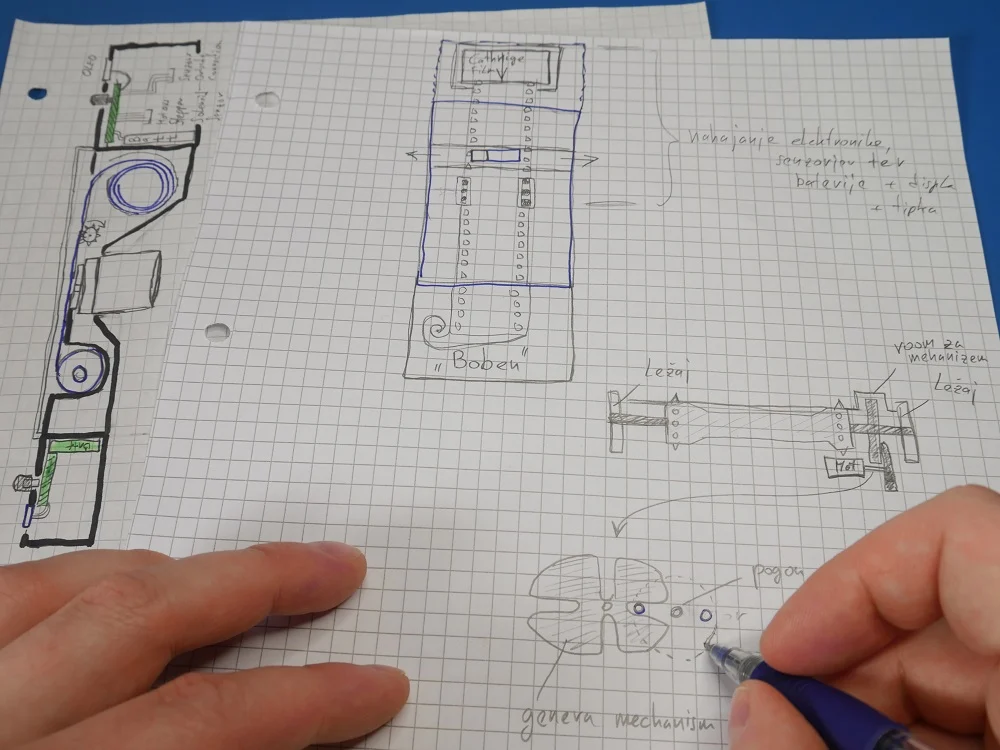

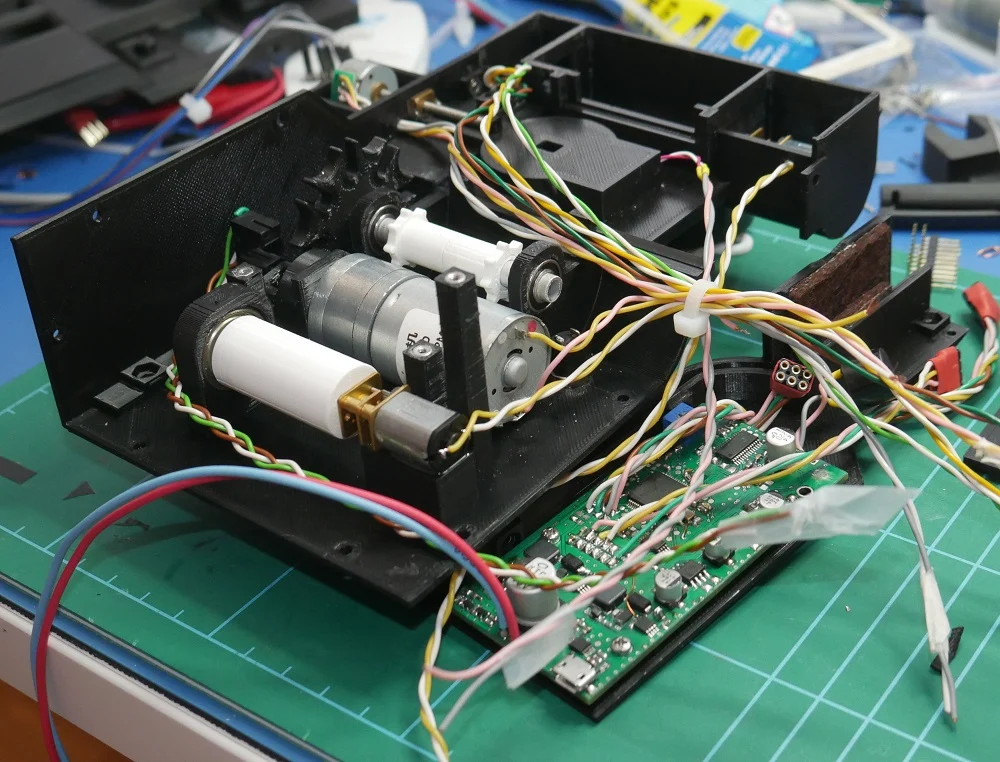

“First, rough sketches of the primary internal camera concept and how it worked were made on paper. The initial action would be to move the film forward by one perforation hole when the blanking gap came around. Here, I’ve chosen the Geneva mechanism, which can change a DC motor’s constant rotating motion into a sprocket gear’s intermittent rotating motion. On a simple platform, a simple 8-position Geneva drive with a sprocket gear was drawn on a computer and then 3D printed. It moves the 35mm film by exactly one sprocket hole for each complete turn of the motor axis.” -Blaž Semprimožnik

Photo courtesy of Blaž Semprimožnik

Photo courtesy of Blaž Semprimožnik

“After the tests went well, other parts were added, such as a guide plane for moving film from a motorized 35mm cartridge holder to a take-up drum, a motorized C-mount shifter for choosing film track exposure with a built-in solenoid light shutter, and a space for a printed circuit board, a battery, and a display. The main base, spacers, and screws held most of these parts in place.”

“The camera was also meant to have an easy way to load film that didn’t require pre-slicing, combining, or loading from an outside reel. Instead, you drop in a regular 35mm cartridge and are ready to go. For the lens, I wanted to be able to switch out lenses. I picked the C-mount system because it has a wide range of options, from comprehensive to telephoto, is cheap, and is still being made. Almost all of the parts were 3D made from black PLA plastic so that no light could get in from the outside.” -Blaž Semprimožnik

Image credit: Blaž Semprimožnik

“The primary objective was to locate the mix between how many frames fit on the cartridge and how big each frame is. Here, I concluded that the frame size should be the same as or bigger than Super8.”

“Other goals included making the camera easy to use and comfortable to hold, having a good user interface with a display, many useful functions, a fully automatic way to feed and wind the film, and being able to scan developed film in some way.”

“Compared to the Super8 format, this would make making films much cheaper and more useful. And 35mm film is much easier to process at home than Super8.”

After thinking about his choices for a better solution, Bla started from scratch by designing, printing, and building a working analog movie camera that could use cheap 35mm film cartridges. The Okto35 came into being!

This Geneva-mechanism camera has a lot of 3D-printed parts, like a guide plane, a take-up drum, a motorized C-mount shifter (which lets a built-in solenoid light shutter choose which film track to expose), a case that can hold different lenses and a DC motor.

Semprimožnik explains how the process works: “A user-friendly GUI with a simple menu system navigation using a joystick button and four different modes of operation: Movie, Photo, Time-Lapse, Scanner, and a system that gathers and processes all data and shows it to the user, such as measured exposure values, remaining recording time, current/saved settings, etc.

“Near the end of coding, many other useful features were added, such as a timer, different ways to use the record button, and a warning system that can be seen and heard. In the STM32 IDE system, programming was done in the C language.”

If you understand any of it, then you can follow Semprimožnik’s instructions to create your very own (opens in a new tab). In any case, Semprimožnik’s project shows that there are ways to make movies on film that don’t cost a lot of money.

Final Thoughts

If you want to try out a 35mm film camera that was made with 3D printing, there are some ways to get started. Many websites and groups have information and help for 3D-printed 35mm film camera. Some online stores sell 3D-printed 35mm film camera and the needed parts and extras.

With some work, you can easily make your own 3D-printed 35mm film camera and enjoy the nostalgic look of film photography without the high cost of standard film cameras.